Sooner or later, as balers evolved, the bale thrower was developed, getting rid of needing another person to stand about the wagon and get the concluded bales. The main thrower system applied two rapid-going friction belts to grab concluded bales and toss them at an angle up during the air onto the bale wagon.

A smaller kind of stacker or bale seize Bale Sledge: In Britain (if tiny square bales remain to be used), they are generally collected as they drop out from the baler inside a bale sledge dragged guiding the baler. This has four channels, managed by automated mechanical balances, catches, and springs, which form Every single bale into its place in the sq. 8. When the sledge is full, a capture is tripped automatically, and a doorway on the rear opens to go away the eight lying neatly together on the bottom.

These teams is often sure with twine for stack stability[14] or not and become stacked on wagons or trailers for transport to storage. These groups are perfect for storage in structures available to gear. This is often also The perfect way to automate bales and likewise allow for them to treatment thoroughly.

The material is crushed, flattened and compressed into a condensed bale inside the baling chamber with the baling equipment. The bale is then tied with baling wire and ejected.

Numerous crops are no challenge for that LSB balers. Properly shaped bales, coupled with significant output and outstanding toughness, make sure the KUHN big square hay baler might be a rewarding investment decision.

In certain cases, servicing could possibly be scheduled extra routinely depending on the scale with the baler and the amount use or substance it receives.

There are many approaches to handle modest bales immediately and eliminate hand labor Nearly absolutely. Bale stackers, bale bundlers, bale accumulators, and bale sledges are the different types of those devices.

KUHN spherical and square balers are constructed with field performance, bale good quality and bale density in mind to help profitability of every baling here Procedure.

Ejection: As soon as the bale is tied, the baler’s chamber is opened, and the finished bale is ejected or pushed out from the device onto a System or conveyor belt. The bale is then moved to the storage space.

Clean quality bales are the basis of a successful hay Procedure. And with John Deere Environmentally friendly-GARD hay preservative, you can waste balers keep the freshness, colour and top quality of every type of hay by inhibiting mould development, heating and spoilage.

It also minimizes the number of collections you would like, reducing site website traffic, nearby environmental affect and overall CO2 emissions.

Round baler dumping a fresh new bale The most common variety of baler in industrialized nations now is definitely the round baler. It generates cylinder-formed "round" or "rolled" bales. The design includes a "thatched roof" influence that withstands climate.[3] Grass is rolled up Within the baler employing rubberized belts, fastened rollers, or a combination of the two. If the bale reaches a predetermined sizing, both netting or twine is wrapped all over it to carry its form. The back again on the baler swings open, plus the bale is discharged. The bales are finish at this stage, However they might also be wrapped in plastic sheeting by a bale wrapper, either to maintain read more hay dry when stored outside or transform damp grass into silage.

We are focused on finding the best baler device for your enterprise. Each individual of our parts of kit provide special Positive aspects. Down below are the primary recycling balers that we offer:

Whichever model fits your requirements, we possess the baler equipment for you personally. A recycling baler will work efficiently to compress your recyclables into tight, neat bales. This makes it less complicated to move and system your online business waste.

Charlie Korsmo Then & Now!

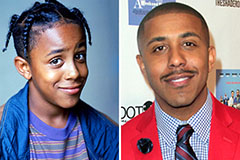

Charlie Korsmo Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now!